Written by Dr Alan Burden , QUT Postdoctoral Research Fellow, Designing Socio-Technical Robotics System program.

A colleague recently questioned why we are building robots that look human. If other machines already perform tasks reliably, robots in human shapes reveal more about our expectations rather than about technical necessity. Apart from striving to fulfil sci-fi fantasies, there seems to be little logical reason for many industries to develop humanoids.

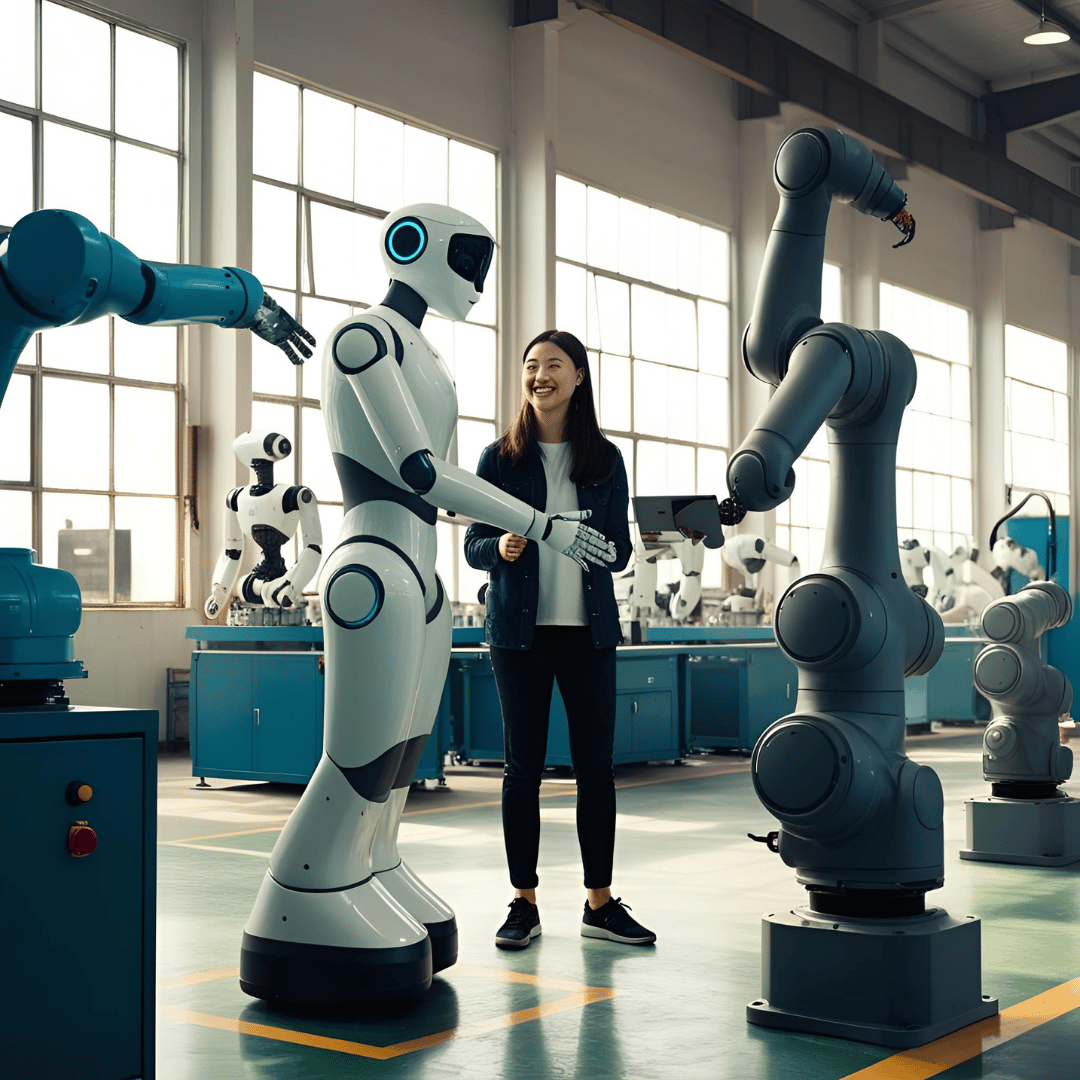

Humanoid robots are machines designed to resemble and move like humans, typically featuring an identifiable head, torso, arms, legs, and enabling interaction with people, objects, and environments in human-centred ways.

In 2025, manufacturers are projected to ship approximately 18,000 humanoid robots globally [1], marking a significant step toward broader adoption. Looking ahead, Goldman Sachs forecasts that by 2035, the humanoid robot market could reach USD $38 billion (approximately AUD $57 billion), with annual shipments increasing to 1.4 million units [2]. Further into the future, Bank of America projects that by 2060, up to 3 billion humanoid robots could be in use worldwide, primarily in homes and service industries [1].

From Tesla’s Optimus Gen 2 [3] to Figure AI’s Figure 02 [4], the humanoid robot is no longer a figment of science fiction. These robots will walk, lift, talk, and perform factory tasks. Yet beneath the surface of innovation lies a deeper question: Will we build humanoid robots because the human form is genuinely useful, or because it reflects our own image back at us?

In an age where industrial arm robots, wheeled and tracked platforms, and flying drones already perform industrial tasks with precision, the humanoid form can seem like an odd choice. These robots will be complex, expensive to develop, and often over-engineered for the roles they are expected to perform.

So what explains the current fascination with building robots in our own image?

Form vs Function: The Practical Debate

Our world is designed around the human body. Door handles, tools, staircases, and car pedals all presume a body with arms, legs, and binocular vision. Humanoid robots will therefore adapt more easily to our environments.

Still, there is a contradiction worth unpacking. We already have machines that operate far more efficiently without the constraints of two legs and a torso. Amazon’s warehouse bots glide on wheels, carrying shelving units with speed and precision [5]. Boston Dynamics’ Spot, a quadruped, excels at inspections and terrain navigation [6]. Agility Robotics’ Digit uses bipedal bird-like legs to move efficiently through human-centric spaces [7].

Humanoid robots won’t necessarily be more capable but may be more compatible with existing environments, especially where infrastructure redesign would be costly or disruptive. This compatibility advantage will be what Stanford’s Human-Centred AI Institute describes as the affordance of embodied compatibility rather than pure efficiency [8].

The Psychological Shortcut

People respond to humanoid forms with startling immediacy. A robot with a face, a voice, and gestures doesn’t just operate in our space – it socially occupies it.

That connection brings both benefits and barriers. Humanoid robots will be easier to instruct, cooperate with, or trust, especially in care or customer service roles. This intuitive rapport, however, will come at a cost. We’ll also project emotions, intentions, and even moral status onto these mechanical beings. The IEEE’s Global Initiative on Ethics of Autonomous Systems [9] has warned that anthropomorphic design risks confusion over autonomy, trust, and accountability.

A robotic arm making a mistake will seem tolerable. A robot with eyes and facial features doing the same will feel uncanny. The “uncanny valley”, a term coined by roboticist Masahiro Mori in 1970 to describe the discomfort people feel when a robot or virtual character looks almost human, but not quite [10] – will blur the line between tool and companion, worker and being.

Redefining Labour and Power

Humanoid robots will often be pitched as general-purpose labourers: tireless, adaptable, and compliant. In some ways, they’ll echo the 19th-century industrial ideal of the perfect worker.

But this vision raises complex questions. If these machines replace humans in repetitive or hazardous roles, how will we protect the dignity and security of displaced workers? If a robot becomes a “colleague,” what responsibilities will come with that illusion?

The Future of Humanity Institute at Oxford [11] noted that humanoids could contribute to a shift in how we view authority and social dynamics. If robots are always obedient, will we begin to expect the same from people? Automation will soon shape not just job loss, but workplace culture and human behaviour. This connects with human-robot interaction research on anthropomorphic framing and robot deception, which cautions against uncritically assigning social roles to machines [11].

Who Are We Really Building?

At its core, the humanoid robot reflects our self-image. When Boston Dynamics’ Atlas robot performed parkour in a now-iconic demonstration video [12], public fascination was less about mechanics and more about the eeriness of watching something mechanical move with such human-like agility. The video, titled Atlas – Partners in Parkour, showcased robots jumping, flipping, and vaulting through a gymnastics course which triggered both admiration, unease and a wave of social media memes drawing comparisions with Terminator films.

This is not new. From clockwork automatons in royal courts to androids in science fiction, each era’s robots mirror its anxieties and desires. For instance, Hanson Robotics’ Sophia [13] was designed with expressive facial features to promote naturalistic interaction, yet remains polarising and dismissed as novelty. Is it an advancement in social robotics or a symbol of anthropomorphic overreach?

The goal of today’s humanoids reveals our priorities. Tesla’s Optimus will be built to handle repetitive factory work. Figure AI’s humanoids will aim to integrate into warehouse workflows. These designs won’t just be technical – they will symbolise which human qualities we value and which jobs we are ready to relinquish.

The Real Question

As mechanical humans enter our homes and workplaces, we must ask what they will symbolise beyond their specs. Humanoid robots will reflect assumptions about work, social interaction, and human worth. When we automate tasks in human form, we choose which parts of ourselves we replicate and which we outsource.

The most pressing questions won’t be about joint torque or facial recognition, but about how these machines reshape our relationships with technology, labour, and each other. Robots, like all tools, embody human intention. The challenge isn’t building minds like ours, but questioning why we keep giving them our face.

References

[1] Koetsier, J. (2025, April 30). Humanoid robot mass adoption will start in 2028, says Bank of America. Forbes. https://www.forbes.com/sites/johnkoetsier/2025/04/30/humanoid-robot-mass-adoption-will-start-in-2028-says-bank-of-america/

[2] Goldman Sachs. (2024, January 8). The global market for humanoid robots could reach $38 billion by 2035. https://www.goldmansachs.com/insights/articles/the-global-market-for-robots-could-reach-38-billion-by-2035

[3] Tesla. (2023). Tesla Optimus: Our Humanoid Robot. https://www.tesla.com/AI

[4] Figure AI. (2024). Figure 02 Robot Overview. https://www.figure.ai/

[5] Amazon. (2025). Facts & figures: Amazon fulfillment centers and robotics. https://www.aboutamazon.co.uk/news/innovation/bots-by-the-numbers-facts-and-figures-about-robotics-at-amazon

[6] Boston Dynamics. (2025). Spot | Boston Dynamics. https://bostondynamics.com/products/spot/

[7] Agility Robotics. (2025). Digit – ROBOTS: Your Guide to the World of Robotics. https://www.agilityrobotics.com/

[8] Srivastava, S., Li, C., Lingelbach, M., Martín-Martín, R., Xia, F., Vainio, K., Lian, Z., Gokmen, C., Buch, S., Liu, K., Savarese, S., Gweon, H., Wu, J., & Fei-Fei, L. (2021). BEHAVIOR: Benchmark for Everyday Household Activities in Virtual, Interactive, and Ecological Environments. arXiv preprint arXiv:2108.03332. https://arxiv.org/abs/2108.03332

[9] IEEE Global Initiative on Ethics of Autonomous and Intelligent Systems. (2020). Ethically Aligned Design, 1st ed. https://ethicsinaction.ieee.org/

[10] Mori, M. (1970). The uncanny valley. Energy, 7(4), 33–35. (English translation by MacDorman & Kageki, 2012, IEEE Robotics & Automation Magazine). https://doi.org/10.1109/MRA.2012.2192811

[11] Brundage, M., Avin, S., Clark, J., Toner, H., Eckersley, P., Garfinkel, B., … & Amodei, D. (2018). The Malicious Use of Artificial Intelligence: Forecasting, Prevention, and Mitigation. Future of Humanity Institute, University of Oxford. Retrieved from https://arxiv.org/abs/1802.07228

[12] Boston Dynamics. (2021, August 17). Atlas | Partners in Parkour [Video]. YouTube. https://www.youtube.com/watch?v=tF4DML7FIWk

[13] Hanson Robotics. (2025). Sophia the Robot. https://www.hansonrobotics.com/sophia/