Written by Postdoctoral Research Fellow, Dr Alan Burden from the Designing Socio-technical Robotic Systems research program in the Centre.

The rise of collaborative robots (cobots) is a game-changer for various industries. These robots are designed to work alongside humans, enhancing productivity and efficiency. However, the real challenge lies in making this human-robot interaction as seamless as possible. Augmented Reality (AR) is a technology that has the potential to revolutionise this space by overlaying digital information onto our physical environment.

The Shift in Cobot Interfaces

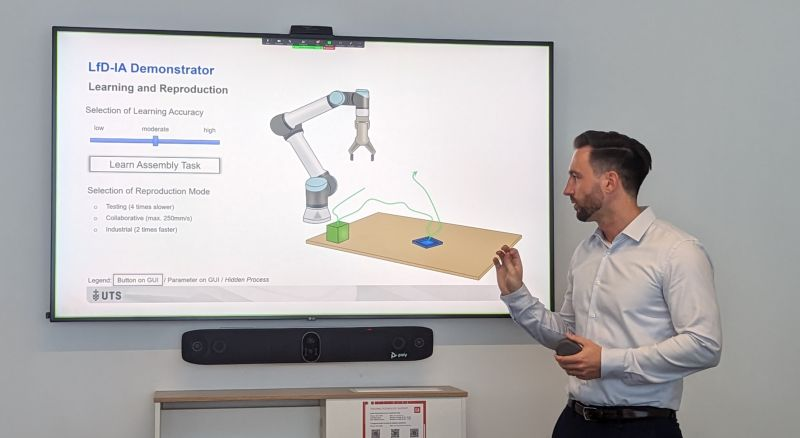

Traditionally, human-cobot interactions have been facilitated through screen-based interfaces or specialised hardware. While these methods are functional, they often require a strenuous learning curve and can be less intuitive. Augmented Reality offers a paradigm shift. By overlaying digital guides, data, or even real-time analytics onto a workspace, AR can make the interaction with cobots more straightforward and efficient. This reduces the time needed for task completion and makes the process more intuitive, reducing the need for extensive training. As we move forward, we are poised to transition from digital 2D interfaces to more immersive 3D interfaces, further enhancing the user experience.

UX Design Principles in AR

User Experience (UX) design is pivotal in making AR-based cobot interaction effective. The objective is to create interfaces that are not just visually appealing but also user-friendly and functional. This involves a deep understanding of the user’s needs, their tasks with the cobot, and the environmental factors at play. For example, an AR interface for a cobot in a medical lab would need to consider sterility and precision. At the same time, one in a manufacturing setting might focus on speed and durability. The design process should be iterative, continually involving users in testing to refine the interface.

User Journey Mapping

Mapping the user’s journey is an invaluable tool in this design process. It involves creating a visual representation of all the interaction points between the user and the cobot facilitated by the AR interface. This helps identify potential issues, bottlenecks, or areas for improvement in the interaction process. For instance, if users find it challenging to access certain information quickly, the interface can be tweaked to make that data more readily available. The ultimate aim is to make the AR interface a tool that enhances, rather than hinders, productivity and user satisfaction.

Safety and Ethics

While AR offers many advantages, it raises important ethical and safety considerations. Data privacy is a significant concern, especially when sensitive or proprietary information is displayed in a shared workspace. The AR interface must also be designed to minimise distractions that could lead to safety hazards. For example, overly flashy or intrusive graphics could divert the user’s attention from critical tasks, leading to accidents. Therefore, ethical guidelines and safety protocols must be integrated into the design process.

What’s Next?

As AR technology continues to evolve, the possibilities for its application in cobotics are virtually limitless. Future developments could include gesture-based controls, adaptive learning algorithms that tailor the interface to individual user preferences, and even real-time collaboration features that allow multiple users to interact with a single cobot. These advancements will make the interaction more seamless and open new avenues for automation and efficiency in various industries.

As we stand on the brink of a new era in human-robot collaboration, enabled by the transformative power of Augmented Reality, we must pause to consider some critical questions.

Will AR interfaces become the new standard in cobotics, making traditional interfaces obsolete?

If we integrate more advanced features like gesture controls and adaptive learning algorithms, are we also prepared to address the complex ethical and safety considerations that come with them?

These questions serve as a reminder that while technology offers immense potential for improvement and innovation, it also demands a level of responsibility and foresight. As we navigate this exciting frontier, let’s ensure our approach is technologically advanced, ethically sound, and user-centric.

Anushani Bibile

Anushani Bibile

Nadimul Haque

Nadimul Haque