Humanoid robots have captured the public’s imagination with their awe-inspiring demonstrations, from backflips and dances to folding laundry. These performances often leave us in awe of their capabilities, showcasing highly sophisticated technology. But at the heart of these demos lies a crucial distinction that is often overlooked: what these robots can do in controlled environments is vastly different from what they can achieve in the real world.

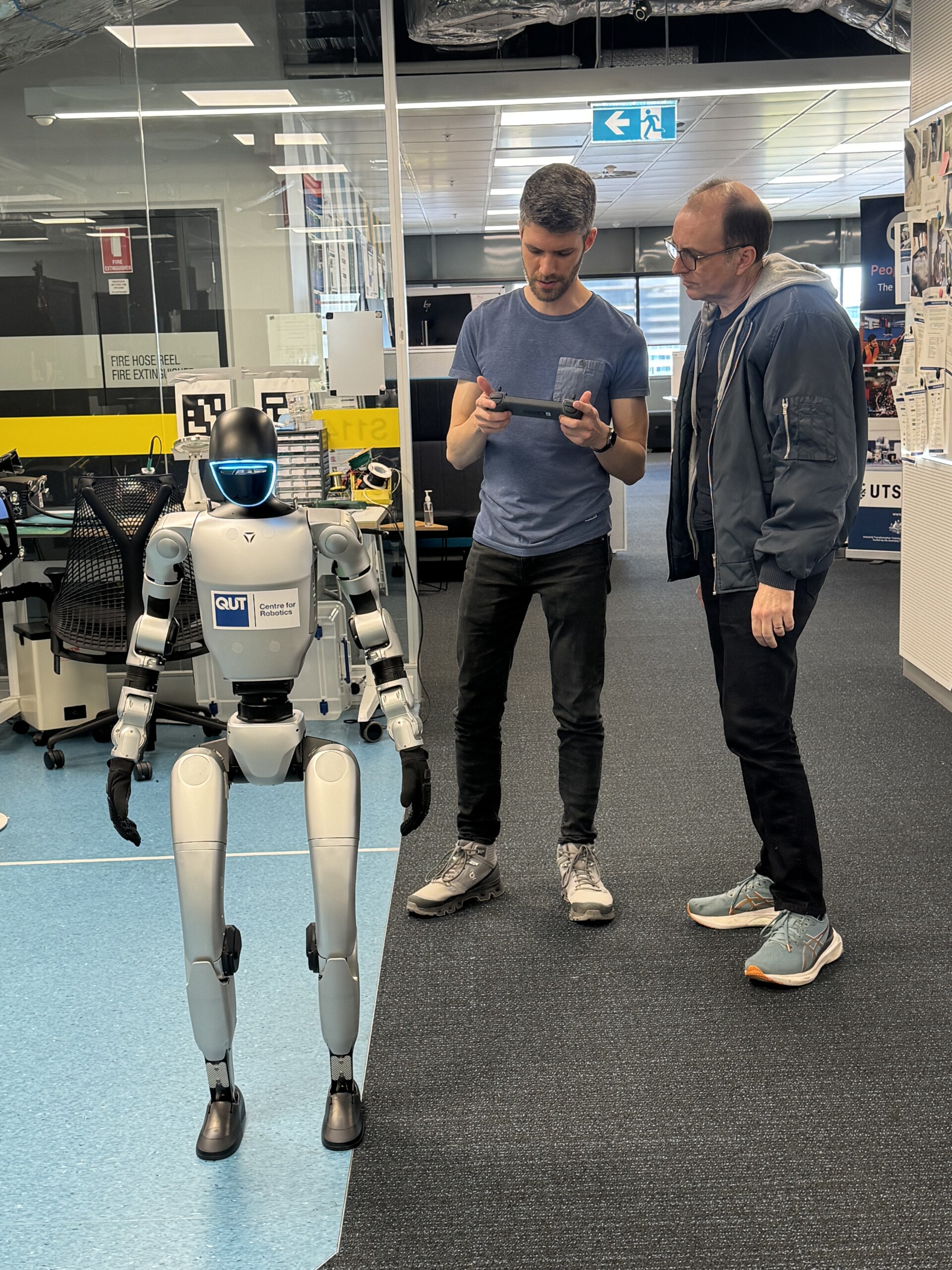

At Swinburne University of Technology (SUT) and Queensland University of Technology (QUT) researchers are shifting the focus from simply impressing audiences to solving the real challenges that come with integrating humanoid robots into everyday environments. Their work aims to bridge the gap between performance-based robotics and true autonomy.

Performance vs. Perception in Humanoid Robots

Most advanced humanoid robot demonstrations rely heavily on predefined motion sequences, scripted environments, and external assistance. The robots perform complex tasks by following a series of carefully orchestrated routines, often created through motion capture, reinforcement learning, or imitation learning in simulated settings. While visually stunning, these robots lack the semantic understanding and real-time reasoning necessary for true independence.

In the real world—whether in homes, hospitals, or factories—robots need much more than impressive pre-programmed actions. They need to:

-

Understand the context of objects and their surroundings

-

Sense the environment in real-time

-

Adapt their control and actions to handle the unpredictable nature of the world

This ability to adapt and truly comprehend is one of the greatest challenges facing robotics today. It’s not enough for robots to simply perform well in rehearsed routines. They must also be able to perceive and respond to dynamic environments.

Collaboration for Real-World Applications

At SUT, the research is aimed at developing humanoid robots that can interact with the world as we do: through contextual awareness and adaptive control. The team is working to address the gap between what robots can perform and how they understand the world around them, an essential step toward making robots more practical for real-world applications.

In this exciting area of research, SUT is eager to collaborate with industry partners to explore collaborative opportunities for research, development, and innovation. The goal is not just to impress but to create robots that can interpret and respond meaningfully to their environments, paving the way for their deployment in real-world scenarios.

As the Australian Cobotics Centre continues to explore the diverse capabilities of collaborative robots (cobots), we look forward to seeing how these advancements in humanoid robotics will contribute to the broader field. Whether in healthcare, manufacturing, or beyond, the future of humanoid robots is about intelligence, not just impressive demonstrations.